Guide to select an efficient Industrial Air Conditioning System

Guide to select an efficient Industrial Air Conditioning System

Choosing the most suitable industrial heating system is essential to ensure efficiency and comfort in any environment.

We want to point out that although IES develops Electric Heat projects providing engineering solutions within highly competitive markets such as energy, industry, and transport, it also produces a wide range of more commercial equipment, all included in a standard product catalog for Industrial Comfort. These devices, due to their composition and design, are ideal for quick installations with effective results, mainly focused on the winter period.

This article aims to guide in choosing the most suitable electric heating equipment for each situation. Our focus will be on the simplest nature heat transfer systems, aiming to provide thermal comfort and ensure a comfortable work or social environment.

Since each company and application has specific requirements, it’s crucial to understand the available options and how they fit the specific needs of your business.

Infrared Heating and Convection Heating

Firstly, we must understand the fundamental differences between the two most common industrial heating technologies: infrared heating and convection heating, two heat transfer methods.

Infrared Heating

This method relies on the emission of infrared radiation to heat objects or people, rather than heating the air. It’s especially effective in environments where rapid heating and precise temperature control are required. Infrared heating is ideal for applications such as paint drying, plastic curing, or maintaining specific work areas at a constant temperature. It requires the anchoring of infrared ray emitters in stable places like walls or ceilings and must be connected to the electricity to work.

Infrared waves are divided into three main categories, each with different wavelengths and applications.

- Short wave directly heats the body it strikes, wasting less energy as the heat is more direct and intense, like a melting furnace.

- Medium wave has intermediate wavelengths and is useful for heating solid and liquid objects, as well as larger areas, for example, a radiation heater to heat a room.

- Long wave is ideal for heating large areas and objects that require constant, gentle heat, suitable for outdoor heating applications like an outdoor patio heater.

At IES Soler, experts in industrial comfort, we offer infrared radiation heat emitter products, from the more industrial RI-S and RI-D models, composed of one or two tubular elements, to the more commercial range infrared radiators RI-EXT, PIM, or HOTTOP with IP for outdoors and various combinations for wall, ceiling, umbrella mounting, etc.

Convection Heating

Unlike the former, convection heating focuses on heating the air in a space, produced by a fluid, either liquid or gas. Convection systems work by heating the air and allowing it to distribute evenly throughout the area. This approach is suitable for heating large warehouses, industrial buildings, and all kinds of spaces where a constant temperature is needed.

Convection heating transfers heat through the movement of hot air or fluid, and the types of heat are classified according to the nature of this.

- Natural convection transfers due to density differences in a fluid, generally air that when hot tends to rise and when cold to descend, creating a natural convection flow, an example would be heating a room with a radiator placed under a window.

- Forced convection is when a device like a fan or a forced air heating system moves hot air through a space in a controlled and fast manner, like a central heating system in homes that use forced convection.

- Lastly, mixed convection, which combines elements of natural and forced convection, the movement of hot air is driven partly by density differences and partly by a ventilation device, an example would be a base heater.

What differentiates this system from infrared heating is that this technology heats the air around the object emitting heat, and as a result, the environment warms up, causing the air to circulate naturally. Also, convectors have resistances that, when powered by electricity, heat the air flowing through them and emit it to the environment, saving the addition of a fan that pushes the air through the system.

At IES Soler, experts in industrial comfort, we offer the following convection heat emitter products: from a simple CEM convector to a full range of walls and portable fan heaters AER-ME and AER-PE available in ranges from 3.2 to 27kW and with the anti-explosion option for ATEX classified areas.

Keys to Industrial Air Conditioning

Industrial air conditioning refers to the process of controlling and maintaining environmental conditions in industrial settings to ensure a suitable and safe environment for the people working there, as well as optimizing industrial processes. This involves regulating temperature, humidity, air quality, and in some cases, atmospheric pressure within an industrial facility.

In this context, at IES, we stand out for our focus on electric heating, a cleaner and safer option compared to gas or fuel oil. Electric heating is not only easy to install, but also can be powered by renewable energy sources, making it environmentally friendly. This means that industrial facilities opting for this type of electric heating have the potential to become zero CO2 emission facilities, thus contributing to sustainability and environmental protection.

Industrial air conditioning is essential in many industries for various purposes, such as manufacturing, storage, and research.

What should we consider when choosing our industrial heating system?

- Temperature Control: In many industrial facilities, it’s essential to maintain a constant temperature to ensure the quality of manufactured products. This can include cooling machinery, heating workspaces, or cooling storage areas and ensuring even heat distribution.

- Energy Efficiency: A good industrial air conditioning system minimizes energy waste and seeks to optimize efficiency to keep operating costs as low as possible.

- Humidity Control: In certain industrial processes, whether in automotive material production, chemical, pharmaceutical, or construction elements, it’s crucial to maintain specific humidity levels to prevent unwanted reactions and ensure the quality of the final product.

- Air Quality: In some industries, like electronics or food, it’s essential to control air quality to prevent product contamination and also ensure worker health. This can include air filtration systems to remove contaminating particles or harmful gases.

- Atmospheric Pressure: In certain research or production applications, it may be necessary to control the atmospheric pressure within a facility to replicate specific conditions or ensure process safety.

- Size and Design of the Facility: The size and design of the industrial facility can influence the choice of heating system. The system must fit the company’s dimensions and layout and ensure it can distribute heat evenly in all necessary areas.

- Safety: Safety is a fundamental consideration in all company decisions, especially when installing systems in industrial environments. The heating system must comply with relevant safety regulations and have features to protect against potential fires and overheating.

- Regulations and Standards: Hand in hand with safety considerations, local and national regulations related to such systems in the industry should be checked. It must comply with all applicable standards and regulations, considering the potential environmental impact of the considered system. Options should be environmentally friendly and reduce greenhouse gas emissions.

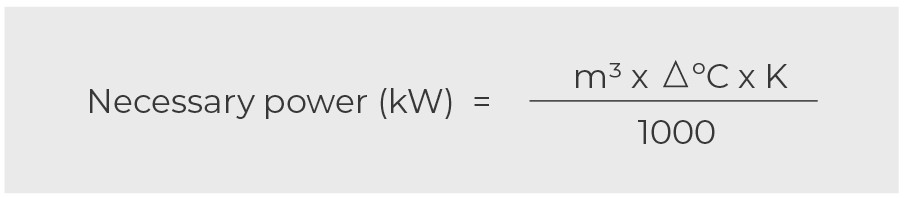

Consult our Industrial Comfort catalog for formulas and indicative calculations for Fan Heaters and Radiators

Industrial air conditioning systems are often complex and must adapt to the specific needs of each industry and location. They can include equipment like heating systems, ventilation, air conditioning, dehumidifiers, air filtration systems, and advanced control systems to maintain required conditions consistently.

In summary, industrial air conditioning manages environmental conditions in industrial settings to ensure process efficiency, the safety of people, and products.